Reasearch and Development

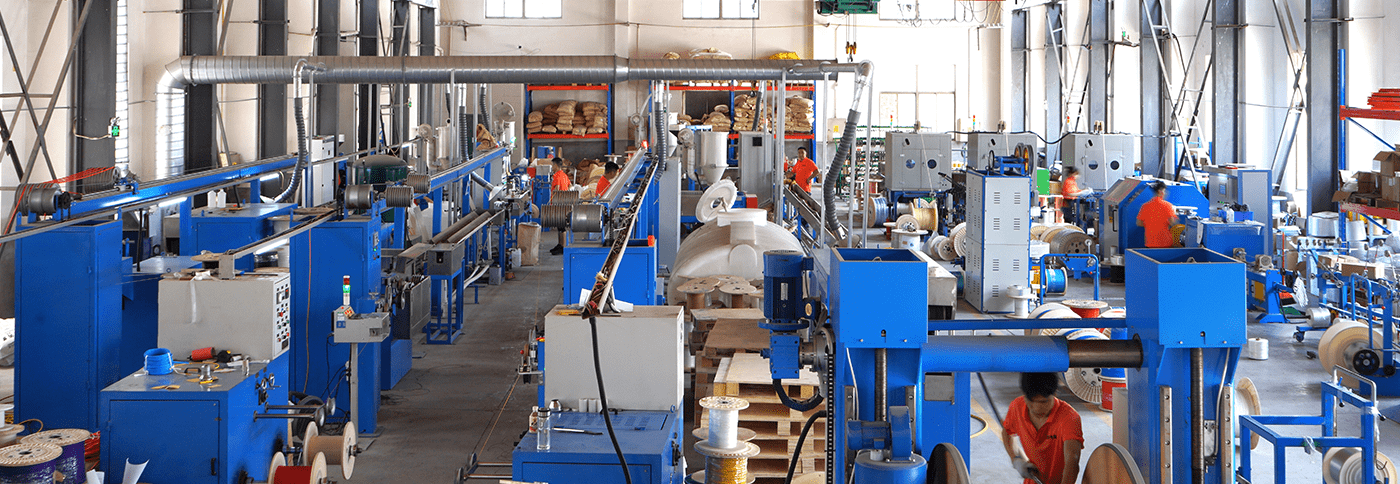

Derul Cable has been emphasizing on improving our product quality and cable innovation for more than 10 years. That helps us keep our competity in global market.

The fast changing market requirement is pushing us to quickly adapt to the newly appearing demands. Our teams have been focusing on smart and effective new solution on how to improve our cable.

To keep exploring new technical possibilities in aspects of material science, we have been updating our testing methods and experimental equipment. New cable design is also an important field that worth our effort. Through all of these, we help our clients gain better product performance.

We always believe that the key to clients' favor is cutting-edge technique, strict material selection, and well control to the manufacturing system.

We spent a lot on our R&D each year. Lab test is one of the key to ensuring the stable quality and new product innovation.

Electric/ Electronic Test

Derul Cable also have close partnership with leading companies which engage in telecommunications, data transmission, industrial automation and offshore & railway segments. The cooperation between us make us better examine our quality by experimental tests. We use equipment to measure the cable's specifications including resistance, capacitance, impedance, return loss, attenuation, cross-talk and skew time. These parameters need to be totally considered during the design and manufacturing of cable.

Furthermore, the CPMS transmission parameters are considered in the test to examine the performance of LAN cable and coaxial cable. Our testing system is generally recognized by major telephone companies.

Resistance Test

Megohmmeter is considered when testing the quality of insulation materials.

Rigidity Test

This test is carried out by AC generator from 2-25 kV.

Current Stability Test

Being carried out by DC generator up to 12 kV.

Operating Voltage Test

Carried out by adapting two high-voltage equipment from 20-30 kV.

High-resolution Electric Resistance Test

Carried out by taking megohmmeter into consideration for cable with cross-section larger than 16 mm².

Physical & Chemical Test

Physical and chemical properties of all cable component must be tested to make sure that all the properties remain still for durability in the cable's entire life-cycle.

Hot Particle Resistance Test

Carried out by applying a hot wire against the cable jacket with a certain pressure during a limited time, for verifying the cable integrity.

Abrasion Resistance Test

Applied to compare the cable's consumption performance under different roughness degrees.

Extreme Temperature Resistance Test

To test the performance of cable under extremely low temperature till -70°C.

Mechanical/ Dynamic Test

For testing the cable performance under frequently dynamic working conditions.

Cable Chain Test

Flexible cable chain with high dynamic performance, small bending radius, high speed and acceleration are outstanding for applications in industrial automation. At present, the capable test is on those cables with radius from 15 mm to 250 mm. The test for drag chain is driven by brushless servo motors.

Robot Work Simulation Test

We use special test to simulate robot movement, with millions of cycles, to ensure the cable's stable performance in automation industry.

Torsion Simulating Test

Special devices are adopted to test the cable's physical parameters including: angle rotation, twisting length, bending radius, speed and acceleration.

Fire Resistance Test

Complying with CEl EN 50200 and CEl EIC 60331.

Fire & Flame Behavior Test

Complying with special international standards for fire & flame resistance.

Quick Links

WhatsApp: +86 13641831061

E-mail: sales@derulkable.com

Add.:No.236 Fenggao Road Fengxian District Shanghai China

Get in touch